Fruit and vegetable processing pumps

Efficient Transport Pumps for Fruit, Vegetables, Tomato Products, and Semi-Liquid Media

Fruit juice production and the processing of fruits, vegetables, and tomato products represent a continuously growing sector, especially in Mediterranean countries such as Italy, Greece, France, and Spain, where favorable climate conditions allow for abundant, high-quality cultivation. From small artisanal workshops to large industrial plants, the primary objective remains the same: to obtain a natural, high-quality product while preserving its organoleptic properties.

The processing of fresh fruit and vegetables—including tomatoes and large fruit pieces—typically begins with cutting, crushing, or extraction, either manually or through automated systems, followed by thermal treatments such as pasteurization to ensure product stability. Throughout every stage of the process—from transferring whole or large fruit pieces, to pumping fresh juice, tomato juice, and concentrated products ready for further processing or bottling—a gentle and controlled transport method is essential to maintain product integrity.

Nova Rotors progressive cavity (monoscrew) pumps are perfectly suited for these applications, ensuring a delicate, pulsation-free pumping action with low shear stress. This allows the safe handling of large fruit pieces, fibrous materials, and high-viscosity products, preventing product degradation, avoiding unwanted emulsification, and preserving the natural structure, flavor, and nutritional value of the processed media.

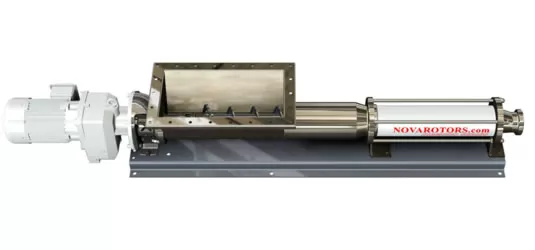

HX SERIES

HXC (compact joint version)- and HXO (Open joint version) Pump with hopper and screw feed, designed for transferring chunky fruit and low-flow products without the formation of blockages.

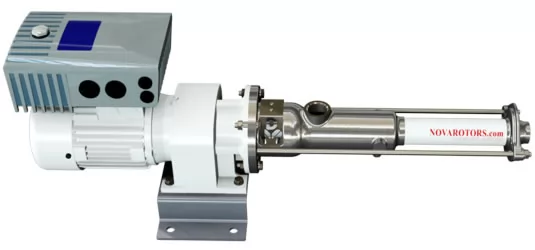

MX SERIES

Hygienic metering pump ensuring precise dosing and consistent performance.To add additive or syrup nad more to the mixer

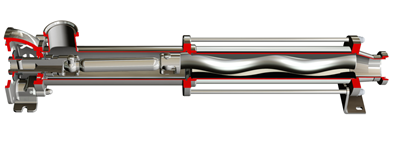

XO SERIES

Hygienic pump with an open joint, made of stainless steel with a design free of water stagnation and dead zones. The optimal solution for transferring natural and pasteurized juices.

XC SERIES

Version with standard Diamond joint, combining excellent hygienic features with a structure optimized for maximum efficiency and cleanliness.

N SERIES

Flanged industrial pump ideal for pumping fruit waste under heavy-duty working conditions. Ensures precise dosing and consistent performance.

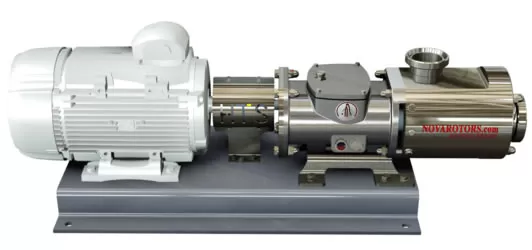

HTS SERIES Pumps

Twin-screw pumps suitable for pumping fluids with varying viscosities, from thinner liquids to very dense ones, including products with large suspended pieces. Useful for tomato, various sauces, and more.

HTS RAPTOR

Twin Screw Pumps

HTS twin screw pumps represent an advanced solution for fluid transfer in the food industry, ensuring high hygienic standards, precise flow control and gentle product handling.

Thanks to their ability to handle fluids with a wide range of viscosities, including products containing suspended particles, they are suitable for numerous food processing applications.

These twin screw pumps are particularly ideal for transferring tomato purée, diced fruit and diced tomato products, preserving product integrity without damage.

The pump is equipped with a base with hygienic feet and a stainless steel motor housing, ensuring maximum hygiene even on external surfaces.

Available with 3-A certification for applications requiring the highest hygienic standards.

MXF Metering Pump

Featuring a jointless titanium shaft, high hygienic standards and 3-A certification, ideal for the transfer of beverages, juices and concentrates.

Designed for the gentle handling of sensitive or corrosive food products, thanks to the excellent resistance of titanium.

Ensures contamination-free product transfer with the highest level of hygienic safety.

Suitable for use in hygienic production environments as well as for CIP/SIP cleaning and sterilization processes, ensuring reliable and repeatable pump cleaning.

Tomato Processing Pumps | Video

Nova Rotors twin screw pumps from the HTS Raptor Series, together with progressive cavity pumps, provide an efficient and reliable solution for pumping tomato products such as pulp, purée, concentrate, diced tomatoes, and vegetable-based sauces. Designed to handle high-viscosity fluids and solids, these pumps ensure gentle product handling, constant flow, and excellent performance even in demanding industrial environments. ✔ Gentle and continuous pumping ✔ Pulse-free flow ✔ High efficiency in food processing ✔ Reliable operation in challenging conditions Nova Rotors pumps comply with Regulation (EC) 1935/2004 and are 3-A Sanitary Standards certified or EHEDG compliant.

Main applications

Handling Chunked Fruit The HX pump is ideal for the gentle transfer of fruit pieces to mixers or processing systems, ensuring a continuous, damage-free transport.

Transfer of Fresh and Pasteurized Juices The X pump is specifically designed for transferring fresh or pasteurized juices at the required temperatures, ensuring a delicate, pulsation-free pumping action.

Pasteurization and Packaging The XO pump, with its hygienic stainless steel design, is perfect for transferring juices during the pasteurization phase and up to bottling.

Transfer of Ready Juices The XO pump, featuring an open joint and high hygienic capabilities, is used for the final transfer of ready juices, preserving freshness and quality.

HTS SERIES Pumps The twin-screw pumps are ideal for pumping diced tomatoes or tomato paste, condiments like pesto, and food oils and fats, which are viscous fluids at high temperatures.

Key strengths

We are a trusted partner in the food processing industry, offering technologically advanced solutions suited to the needs of modern production lines.

- Gentle and Continuous Transport: The monovite pumps ensure controlled movement of fruit, juices, and semi-dense products, preserving their structure and organoleptic qualities.

- Certified Materials: Made from materials compliant with the most stringent sanitary regulations (FDA and EC Regulation 1935/2004), our pumps ensure hygiene and reliability. 3-A Sanitary Standard certified options available.

- Custom Solutions: With a team of experts, we offer tailor-made configurations to optimize every phase of the process, reducing transfer times and operational costs.

Our pumps are designed to handle chunked fruit, sugary juices, and products with a high percentage of solid parts, maintaining a constant, pulsation-free flow. Rigorously tested for durability and performance, they guarantee efficiency, quality, and long-lasting performance in every application.

Let me know if you'd like to make any changes!

A Commitment to Efficiency and the Environment

Our company is dedicated to supporting the fruit and vegetable processing industry with solutions that combine productivity and environmental sustainability. Our pumps are designed to preserve the natural quality of products, reduce waste, and optimize transfer and processing stages.

Thanks to certified materials and advanced hygienic design, we ensure a safe and clean process that meets the highest standards in the food industry. Choosing Nova Rotors means relying on an innovative partner, focused on quality and the future of food processing.

Let me know if you need any adjustments!

Recommended products