Wobble R series

floating stator for Industrial, environmental and food sector

Our range of wobble pumps is the ideal solution for those seeking a highly compact and versatile product. They are particularly easy and economical to maintain, due to the very small number of component parts. They can be used in a variety of industrial applications due to their ability to pump products which are viscous, which have solids in the fluid or which are mildly abrasive. Perfect for those seeking a highly efficient, economical product, these offer an unparalleled cost/benefit advantage. Even at high rpms, they pump without pulsating and there is virtually no centrifugal effect. They are also suitable for use within the food industry, as there are no dead zones within the pump.

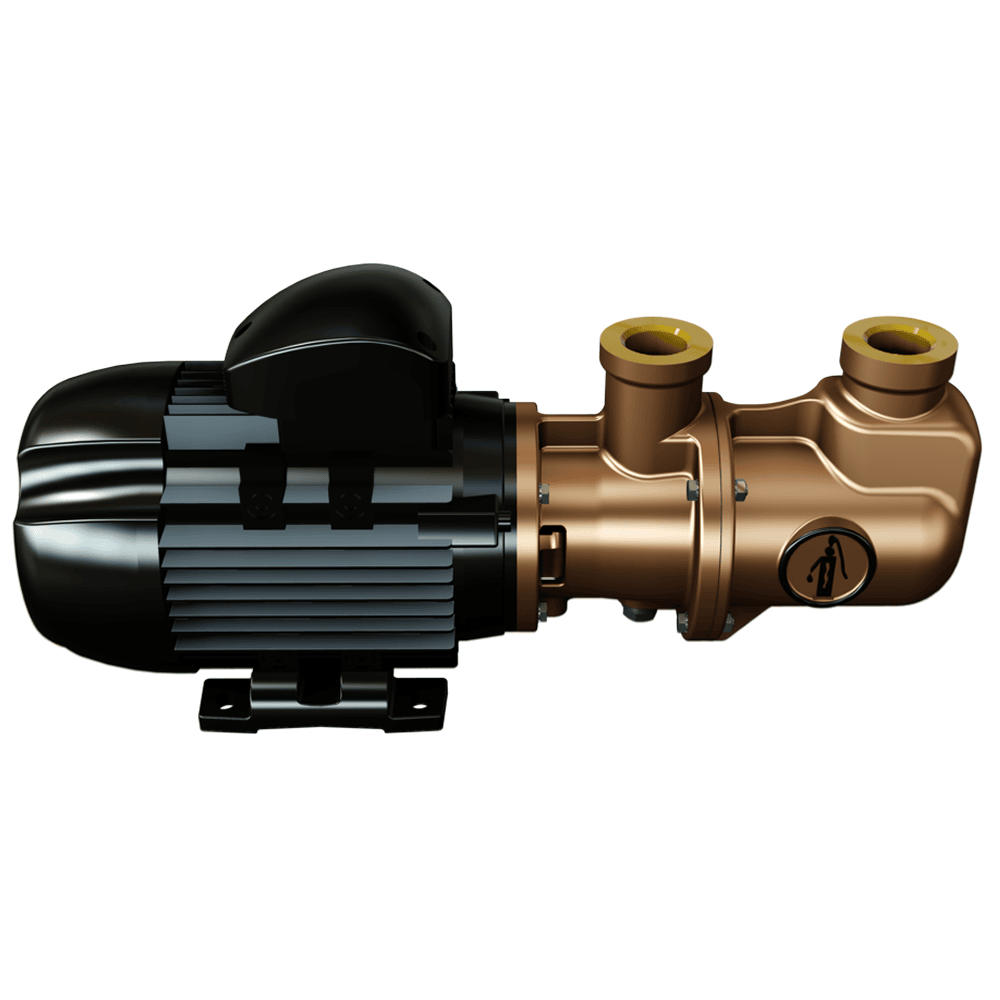

The R series range of pumps all have solidly constructed housings in cast iron, bronze and stainless steel (AISI Type 304 and AISI Type 316), manufactured using lost wax casting technology.

Food use: Stainless steel pumps can be supplied with FDA components or according to UNI EN 1935:2004.

Threaded GAS BSP connections are available as standard, but we can also supply DIN 11851 type adaptors upon request.

Operating ranges

Flow rate

Pressure

Temperature

Applications

Discover the product's application characteristics Wobble R series

Models

| Size | Model | QMAX 1 BAR [m³/h] | RPM | P MAX [bar] |

|---|---|---|---|---|

| - | R24 | 0,55 | 1400 rpm (4ph 0,25 kW) | 4 |

| - | R24 | 0,35 | 900 rpm (6ph 0,18 kW) | 4 |

| - | R28 | 0,33 | 1400 rpm (4ph 0,25 kW) | 4 |

| - | R28 | 0,21 | 900 rpm (6ph 0,18 kW) | 4 |

| - | R45 | 2,7 | 1400 rpm (4ph 0,55 kW) | 4 |

| - | R45 | 1,7 | 900 rpm (6ph 0,55 kW) | 4 |

| - | R45 | 1,3 | 700 rpm (8ph 0,25 kW) | 4 |

| - | R49 | 1,05 | 1400 rpm (4ph 0,55 kW) | 4 |

| - | R49 | 0,67 | 900 rpm (6ph 0,55 kW) | 4 |

| - | R49 | 0,52 | 700 rpm (8ph 0,25 kW) | 4 |

| - | R64 | 3,5 | 1400 rpm (4ph 1,1 kW) | 4 |

| - | R64 | 2,25 | 900 rpm (6ph 0,75 kW) | 4 |

| - | R64 | 1,75 | 700 rpm (8ph 0,55 kW) | 4 |

| - | R68 | 3 | 1400 rpm (4ph 1,1 kW) | 4 |

| - | R68 | 1,9 | 900 rpm (6ph 0,75 kW) | 4 |

| - | R68 | 1,5 | 700 rpm (8ph 0,55 kW) | 4 |

| - | R84 | 5,9 | 1400 rpm (4ph 2,2 kW) | 4 |

| - | R84 | 3,8 | 900 rpm (6ph 1,5 kW) | 4 |

| - | R84 | 2,9 | 700 rpm (8ph 0,75 kW) | 4 |

| - | R88 | 4,2 | 1400 rpm (4ph 2,2 kW) | 4 |

| - | R88 | 2,7 | 900 rpm (6ph 1,5 kW) | 4 |

| - | R88 | 2,1 | 700 rpm (8ph 0,75 kW) | 4 |

| - | R44 | 2,5 | 1400 rpm (4ph 0,552 kW) | 4 |

| - | R44 | 1,7 | 900 rpm (6ph 0,55 kW) | 4 |

| - | R44 | 1,3 | 700 rpm (8ph 0,25 kW) | 4 |

| - | R48 | 1.05 | 1400 rpm (4ph 0,55 kW) | 4 |

| - | R48 | 0,67 | 900 rpm (6ph 0,55 kW) | 4 |

| - | R48 | 0.52 | 700 rpm (8ph 0,25 kW) | 4 |

Materials

Casing materials

Wide selection of cast iron, and stainless steel bodies, including corrosion-resistant options for harsh environments.

Seal Shaft Materials

The R Series is designed to ensure easy maintenance, with only a minimum number of replacement parts necessary. In particular the cross-joint is easy to replace due to its reduced dimensions, enabling it to be completely replaced without having to replace shafts and rotors. Maintenance costs are thus reduced. The cost of the machine is also highly competitive, considering its entire life-cycle.

Materials of Rotors

Steel and special alloy materials long-lasting durability and resistance.

Materials of Stators

We offer a wide selection of compound materials for stators, designed to ensure high performance and durability in diverse industrial environments.

Among the available options, we can provide elastomers and special materials, including food-grade compounds and high-performance solutions.

Connections

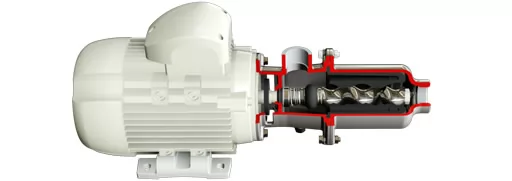

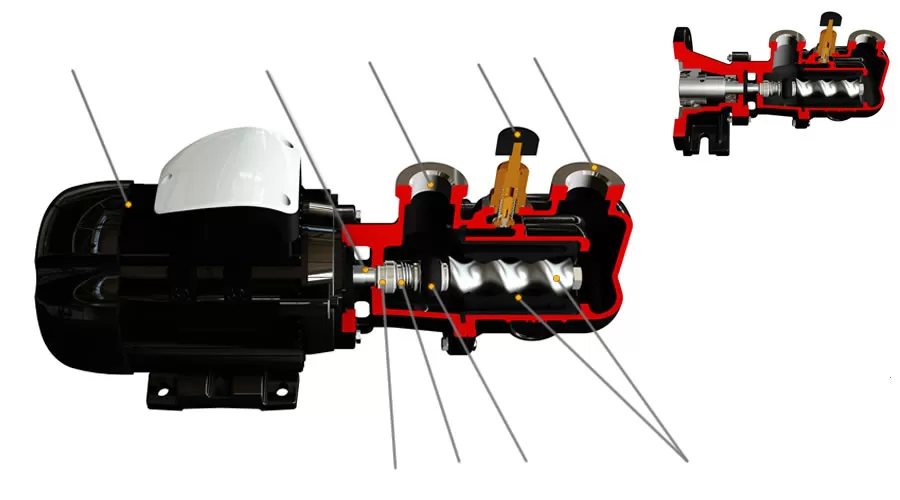

Cross-type joints, the true heart of the wobble pump, offer the best solution currently available on the market. Cast-manufactured, highly durable and reliable, due to the high degree of engineering being achieved. Its special construction allows the axial loads and torques on the two axes of rotation to be split, ensuring only rotary movements of the pins that compose it. Its smaller dimensions mean that it can be replaced quickly.

Sealing Systems

The pump uses internal single mechanical seals as standard. The seal is located inside the pump housing. This solution ensures the maximum heat exchange between the surface of the seal and the product being pumped, which gives the benefit of increased durability. Moreover, the position of the seal makes it much easier to keep clean, thus avoiding product residues that could negatively affect operating conditions. The housings are suitable for the installation of seals manufactured in accordance with ISO EN 12756.

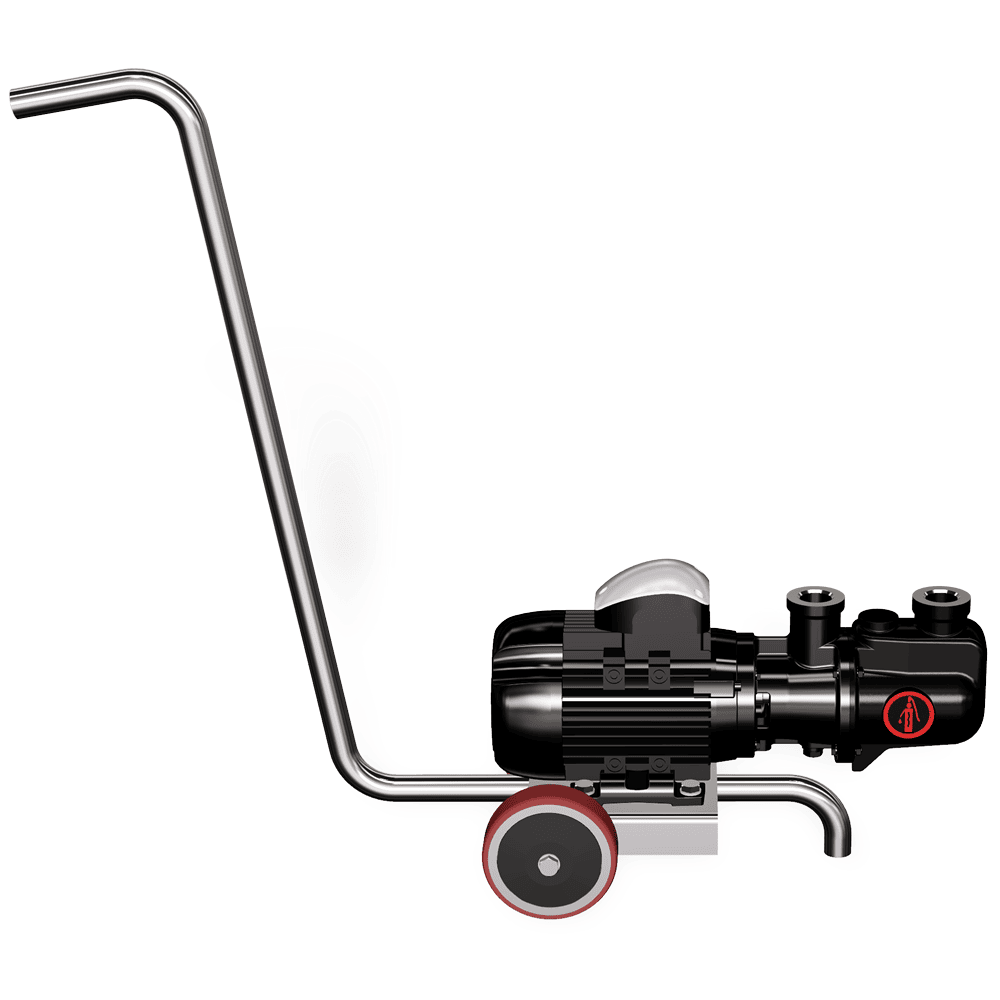

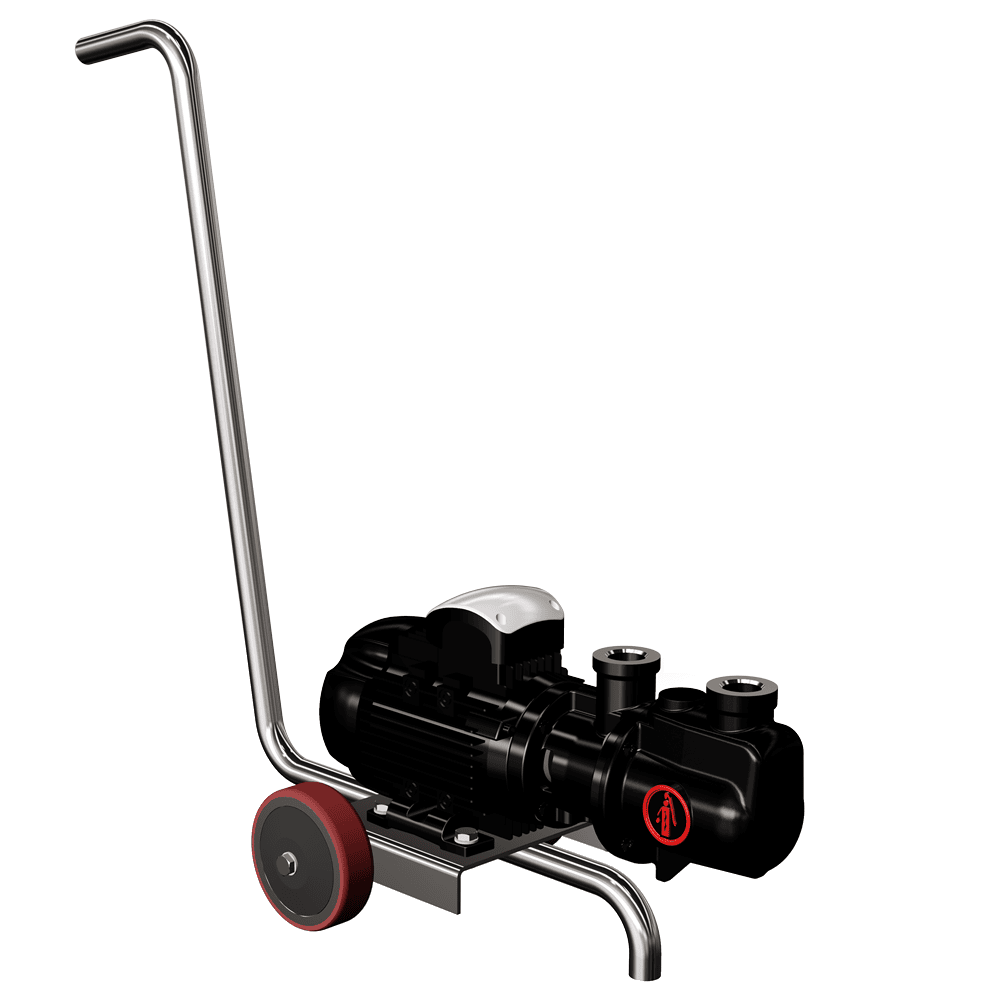

Bases

Standard base

Base with hygienic, anti-vibration, adjustable feet

Base with risers

Trolley for food industry

(For details of construction, please refer to the brochure for options, accessories and fittings)

Optional

By-pass integrated into the pump construction

Stainless steel support block

Protective drive casing

(For details of construction, please refer to the brochure for options, accessories and fittings)

Features in detail

Electric motor integrated

Electric motor Direct coupled DetailsDrive shaft

The seal works directly on the drive shaft. Manufactured in AISI Type 316. DetailsOutlet inlet

Outlet sections designed to reduce pressure losses. DetailsBypass safety valve

Safety valve integrated into the pump construction, for protection against excess pressure. DetailsSuction sections

Wide suction sections enable excellent priming abilities. DetailsRF Series

Modular bearing supports. Ideal for coupling with gearboxes and variable speed drives. DetailsMechanical seal

Single mechanical seal inside the pump housing. DetailsRotating parts

Rotating parts made from stainless steel as standard. DetailsCross-joint

Supplied as a ready-assembled and lubricated KIT. DetailsRotors and stators

Abrasion-resistant rotors and stators enable the pumping of highly viscous fluids and fluids with suspended solids. Details

-

1

Electric motor integrated

Electric motor Direct coupled

Electric motor integrated

into the pump construction.

Direct coupled -

2

Drive shaft

The seal works directly on the drive shaft. Manufactured in AISI Type 316.

This solution eliminates coupling, allowing the seal to work more precisely and giving greater rigidity; it also further facilitates quick and easy maintenance.

-

3

Outlet inlet

Outlet sections designed to reduce pressure losses.

The pump housing can be manufactured in different metals, according to requirements.

GAS BSP and DIN 11851 Connections Available. -

4

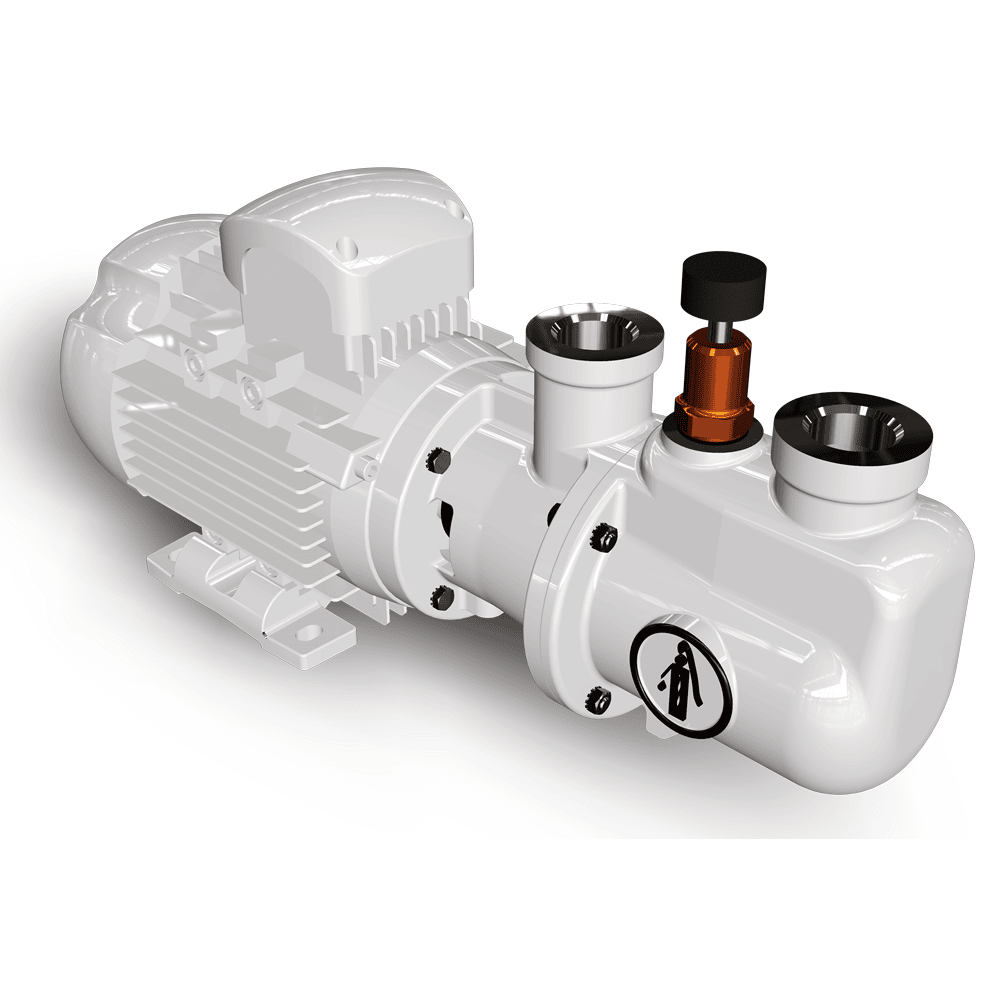

Bypass safety valve

Safety valve integrated into the pump construction, for protection against excess pressure.

Adjustment is fast and simple.

The special construction of this by-pass system allow overall dimensions and costs to be reduced.

-

5

Suction sections

Wide suction sections enable excellent priming abilities.

Wide suction sections enable excellent priming abilities and the efficient pumping of viscous substances. The inlet port can be manufactured in different metals, according to requirements. GAS BSP and DIN 11851 Connections Available.

-

6

RF Series

Modular bearing supports. Ideal for coupling with gearboxes and variable speed drives.

Modular bearing supports exceptionally high-performance bearings for maximum reliability.

Plug-in shaft for direct flange coupling.

Ideal for coupling with reducers and variators. -

7

Mechanical seal

Single mechanical seal inside the pump housing.

A conical spring seal is used as standard.

Highly reliable and easy to install.

Its simple construction enables easy cleaning. -

8

Rotating parts

Rotating parts made from stainless steel as standard.

Rotating parts made from stainless steel as standard, even for cast iron or bronze pumps. Various metals available, depending on the application.

-

9

Cross-joint

Supplied as a ready-assembled and lubricated KIT.

Replacement is therefore extremely quick and easy.

Highly durable, with excellent reliability. -

10

Rotors and stators

Abrasion-resistant rotors and stators enable the pumping of highly viscous fluids and fluids with suspended solids.

The rotor can be supplied in different base metals and heat-treated or coated in order to increase durability.

The stators can be configured with various types of elastomers.

Further details

Electric motor Direct coupled

Electric motor integrated

into the pump construction.

Direct coupled

Further details

The seal works directly on the drive shaft. Manufactured in AISI Type 316.

This solution eliminates coupling, allowing the seal to work more precisely and giving greater rigidity; it also further facilitates quick and easy maintenance.

Further details

Outlet sections designed to reduce pressure losses.

The pump housing can be manufactured in different metals, according to requirements.

GAS BSP and DIN 11851 Connections Available.

Further details

Safety valve integrated into the pump construction, for protection against excess pressure.

Adjustment is fast and simple.

The special construction of this by-pass system allow overall dimensions and costs to be reduced.

Further details

Wide suction sections enable excellent priming abilities.

Wide suction sections enable excellent priming abilities and the efficient pumping of viscous substances. The inlet port can be manufactured in different metals, according to requirements. GAS BSP and DIN 11851 Connections Available.

Further details

Modular bearing supports. Ideal for coupling with gearboxes and variable speed drives.

Modular bearing supports exceptionally high-performance bearings for maximum reliability.

Plug-in shaft for direct flange coupling.

Ideal for coupling with reducers and variators.

Further details

Single mechanical seal inside the pump housing.

A conical spring seal is used as standard.

Highly reliable and easy to install.

Its simple construction enables easy cleaning.

Further details

Rotating parts made from stainless steel as standard.

Rotating parts made from stainless steel as standard, even for cast iron or bronze pumps. Various metals available, depending on the application.

Further details

Supplied as a ready-assembled and lubricated KIT.

Replacement is therefore extremely quick and easy.

Highly durable, with excellent reliability.

Further details

Abrasion-resistant rotors and stators enable the pumping of highly viscous fluids and fluids with suspended solids.

The rotor can be supplied in different base metals and heat-treated or coated in order to increase durability.

The stators can be configured with various types of elastomers.

Variants

R Series

An extremely compact product thanks to the integrated construction between pump and electric motor. It uses the pivot to cruise, to guarantee a reliability very high and reduced footprint. There is no support between pump body and drive in favor of compactness and ease of maintenance.

RF Series

Based on the same technology as the R series. It differs in the use of a bearing holder with hollow shaft input. The RF series can be connected directly to the drive via flange. The ideal solution for the supply of bare-axis pump, while maintaining compactness and ease of installation. The bearings guarantee maximum reliability in any operating condition.

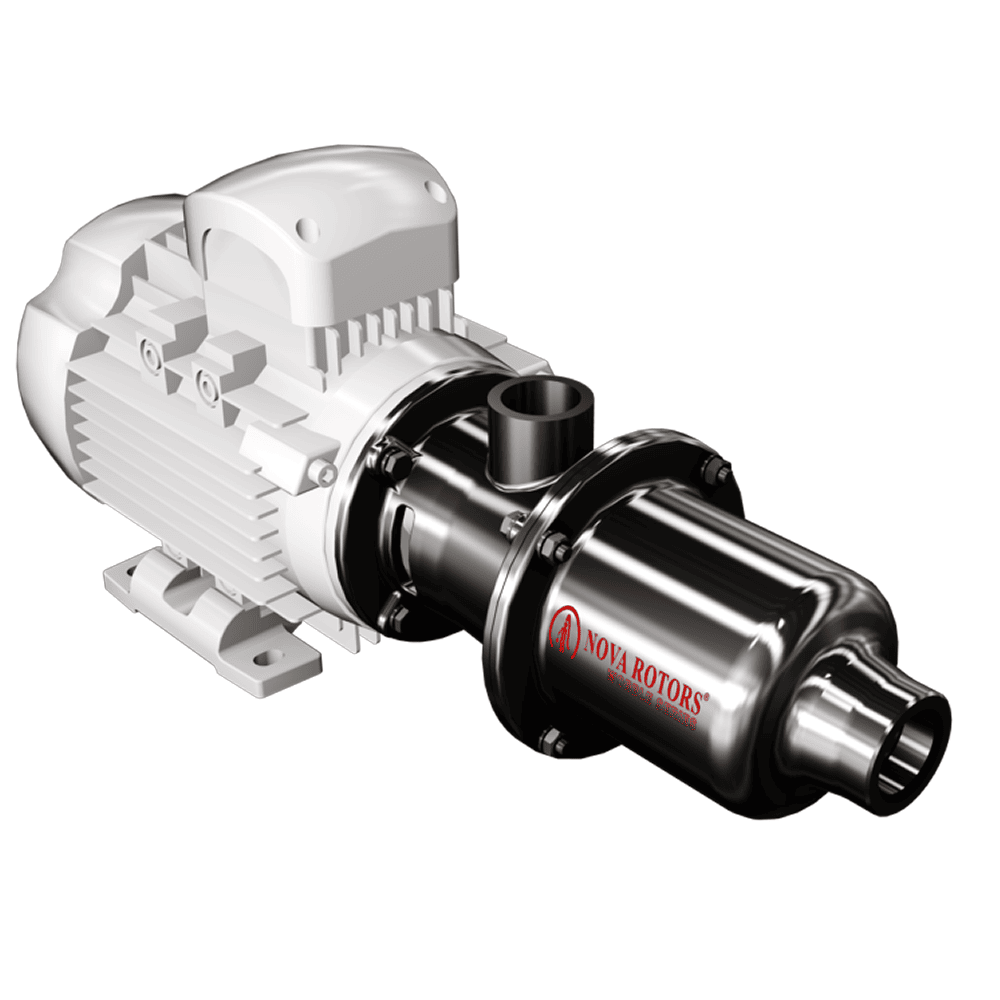

R Series - Inox

An extremely compact product thanks to the integrated construction between pump and electric motor. It uses the pivot to cruise, to guarantee a reliability very high and reduced footprint. There is no support between pump body and drive in favor of compactness and ease of maintenance.

This Wobble R pump stands out for its use of food-grade elastomers, a stainless steel casing, and a stainless steel rotor. It is suitable for use with food products.