Nova Rotors

Bombas y trituradoras

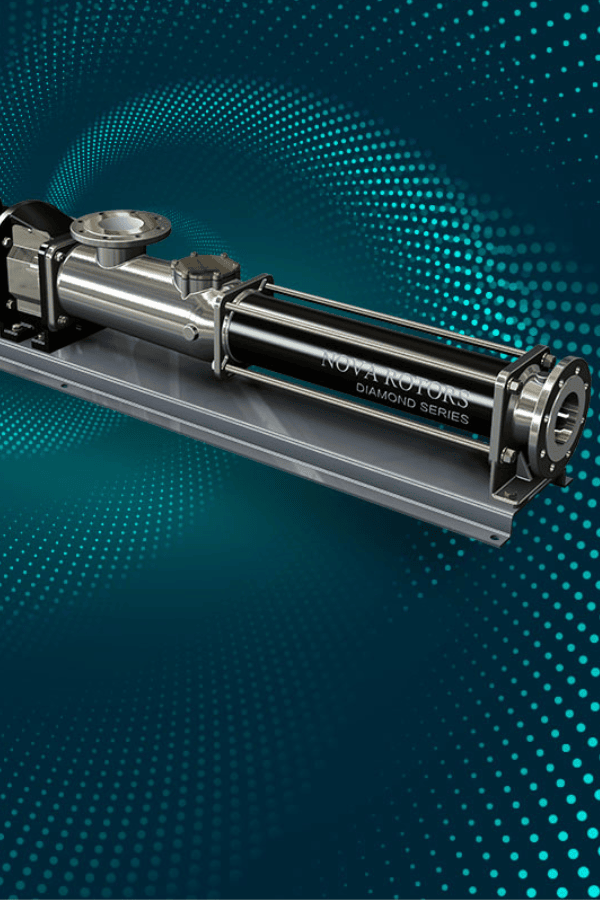

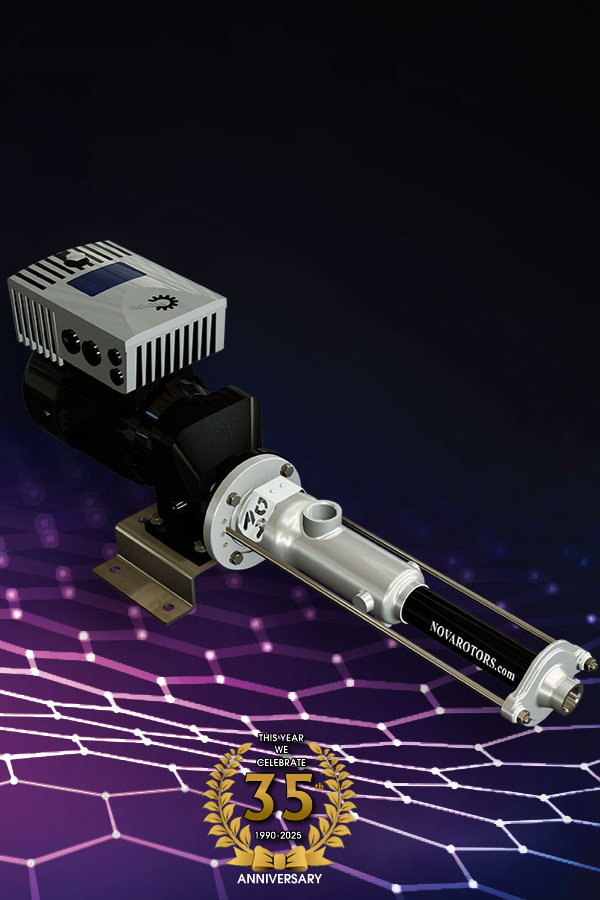

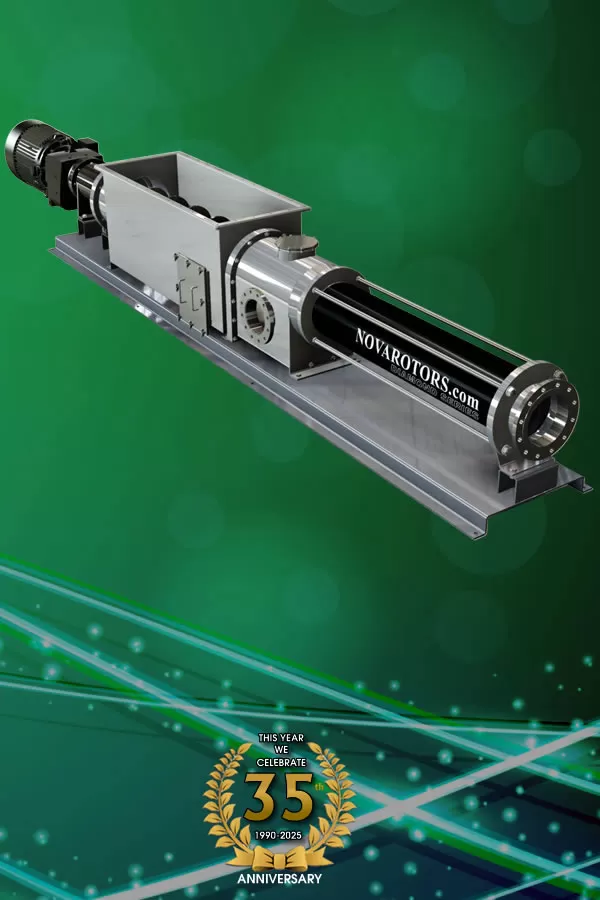

Fundada en 1990, Nova Rotors es hoy una empresa de referencia nacional en la construcción y venta de bombas de cavidad progresiva monotornillo,bombas de doble tornillo, bombas de estator flotante y trituradores.

Distribuidas en todo el mundo, se aplican en una amplia variedad de sectores, desde el tratamiento de aguas hasta la industria en general, desde la viticultura hasta la alimentaria, satisfaciendo las más diversas demandas y necesidades de aplicación.

Fiables y robustas, nuestras bombas garantizan el movimiento seguro y eficiente de fluidos en entornos industriales y marítimos, respondiendo a las demandas más complejas con soluciones personalizadas.

Desde la vinificación hasta la gestión de líquidos en bodegas, nuestras bombas aseguran una transferencia suave y controlada, preservando la calidad y la integridad del producto en cada etapa del proceso.

Máxima higiene y precisión para la industria láctea: nuestras bombas y soluciones de transferencia garantizan calidad, seguridad alimentaria y el respeto por las propiedades organolépticas.

Soluciones ideales para el sector alimentario: nuestras bombas manejan masas, cremas y mezclas con el máximo cuidado, garantizando uniformidad, continuidad en el proceso y calidad constante.

Eficiencia y fiabilidad en la producción alimentaria: nuestras bombas gestionan la transferencia de jugos, bebidas y otros líquidos con delicadeza, optimizando cada etapa del proceso.

Abordamos los desafíos del tratamiento de lodos con soluciones eficientes y sostenibles: nuestras bombas garantizan una transferencia óptima de lodos deshidratados, reduciendo los costes operativos y el impacto ambiental.

Nuestros productos

Aplicaciones

Sea cual sea tu industria – desde el tratamiento de aguas hasta la producción de medicamentos – Nova Rotors es tu socio de confianza para soluciones de bombeo eficientes y fiables.