Progressing Cavity Pumps V series

Vertical pump for industrial, chemical, environmental sector

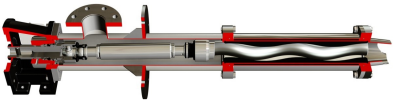

The Vertical series is the ideal solution for pumping from wells or tanks. It is suitable for pumping viscous and non-viscous products as well as abrasive or aggressive ones.

Available with outlet flange connections UNI, DIN, ANSI and GAS BSP; the suction nozzle instead is made with a particular design optimized for priming the product in which it is lost in.

The length is totally customizable according to the setup requirements. The stainless steel version (AISI 304 or AISI 316) has a protective jacket that covers the stator as standard to prevent it from corrosion.

There are two standard configurations availables: the short version and the long version.

The difference is in the length of the installation with which they are required for.

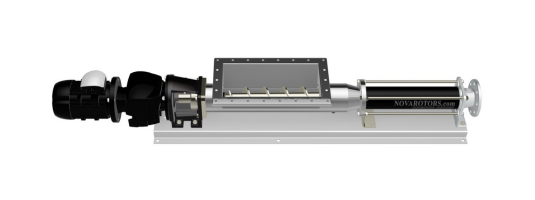

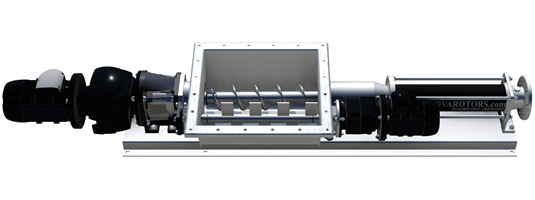

The short version is compact, robust, easy to install.

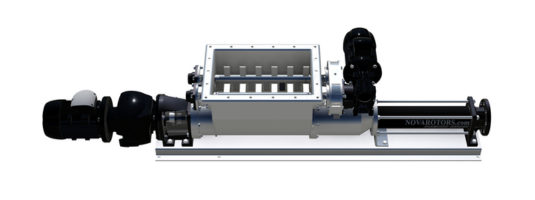

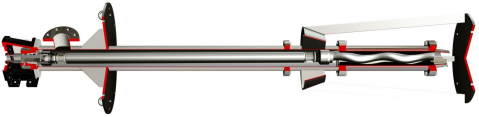

The long version instead allows installation in deep wells or tanks and presents a complete series of dedicated optimizations such as the removable inlet for easy maintenance of the rotor, stator and coupling.

A fundamental characteristic is the support of the downhole support, with a guiding cone which makes the pump very stable and vibration free even in extreme conditions of use.

Both series are always configured in a monobloc arrangement.

Operating ranges

Flow rate

Pressure

Temperature

Applications

Discover the product's application characteristics Progressing Cavity Pumps V series

Models

| Size | Model | QMAX 2 BAR [m³/h] | RPM MAX | P MAX [bar] |

|---|---|---|---|---|

| D020 | 1L1 | 4,9 | 1400 | 6 |

| D020 | 05K2 | 2,5 | 1400 | 12 |

| D020 | 025K4 | 0,7 | 800 | 24 |

| D025 | 2L1 | 10 | 1400 | 6 |

| D025 | 1K2 | 5,1 | 1400 | 12 |

| 05K4 | 05K4 | 1,5 | 800 | 24 |

| D025 | 025K8 | 0,7 | 800 | 48 |

| D030 | 4L1 | 14 | 1000 | 6 |

| D030 | 2K2 | 7,2 | 1000 | 12 |

| D030 | 1K4 | 2,9 | 800 | 24 |

| D030 | 05K8 | 1,5 | 800 | 48 |

| D040 | 10L1 | 22 | 800 | 6 |

| D040 | 4K2 | 11,5 | 800 | 12 |

| D040 | 2K4 | 4,2 | 600 | 24 |

| D040 | 1K8 | 2,4 | 800 | 48 |

| D040 | 16L1 | 32,5 | 800 | 6 |

| D040 | 8K2 | 16,8 | 800 | 12 |

| D040 | 4K2EL | 11,5 | 800 | 18 |

| D060 | 20L1 | 39,1 | 700 | 6 |

| D060 | 10K2 | 17,2 | 600 | 12 |

| D060 | 4K4 | 7,2 | 500 | 24 |

| D060 | 2K8 | 4,2 | 600 | 48 |

| D060 | 30L1 | 46 | 700 | 6 |

| D060 | 16K2 | 21,5 | 600 | 12 |

| D060 | 10K2EL | 17,2 | 600 | 18 |

| D120 | 40L1 | 65,5 | 600 | 6 |

| D120 | 20K2 | 31 | 600 | 12 |

| D120 | 10K4 | 11,7 | 400 | 24 |

| D120 | 4K8 | 7,3 | 500 | 48 |

| D120 | 60L1 | 82 | 500 | 6 |

| D120 | 30K2 | 40,5 | 500 | 12 |

| D120 | 20K2EL | 31 | 600 | 18 |

| D300 | 80L1 | 88 | 400 | 6 |

| D300 | 40K2 | 45 | 400 | 12 |

| D300 | 20K4 | 21 | 400 | 24 |

| D300 | 10K8 | 11,7 | 400 | 48 |

| D300 | 120L1 | 120 | 400 | 6 |

| D300 | 60K2 | 64,5 | 400 | 12 |

| D300 | 40K2EL | 45 | 400 | 18 |

| D400 | 160L1 | 161 | 400 | 6 |

| D400 | 80K2 | 90 | 400 | 12 |

| D400 | 40K4 | 45 | 400 | 24 |

| D400 | 20K8 | 19,5 | 350 | 48 |

| D400 | 240L1 | 261 | 400 | 6 |

| D400 | 120K2 | 116 | 350 | 12 |

| D400 | 80K2EL | 90 | 400 | 18 |

| D400 | 40K2E | 45 | 400 | 24 |

| D400 | 20K4E | 19,5 | 350 | 48 |

| D500 | 320L1 | 255 | 350 | 6 |

| D500 | 160K2 | 142 | 350 | 12 |

| D500 | 80K4 | 56 | 250 | 24 |

| D500 | 40K8 | 26 | 250 | 48 |

| D500 | 480L1 | 368 | 350 | 6 |

| D500 | 240K2 | 185 | 350 | 12 |

| D500 | 160K2EL | 142 | 350 | 18 |

| D500 | 80K2E | 56 | 250 | 24 |

| D500 | 40K4E | 26 | 250 | 48 |

| D600 | 640L1 | 540 | 350 | 6 |

| D600 | 320K2 | 280 | 350 | 12 |

| D600 | 160K4 | 101 | 250 | 24 |

| D600 | 80K8 | 51 | 250 | 48 |

| D600 | 960L1 | 802 | 350 | 6 |

| D600 | 480K2 | 403 | 350 | 12 |

| D6 | 320K2EL | 280 | 350 | 18 |

| D600 | 160K2E | 142 | 250 | 24 |

| D600 | 80K4E | 56 | 250 | 48 |

Materials

Casing materials

Wide selection of cast iron, alloy, and stainless steel bodies, including corrosion-resistant options for harsh environments.

Coatings

On request, solutions such as fluoropolymers and ceramic coatings to ensure superior performance.

Seal Shaft Materials

Steel and special alloy materials with advanced coatings to ensure long durability and resistance, as well as advanced protective coatings such as ceramic oxides and tungsten carbide.

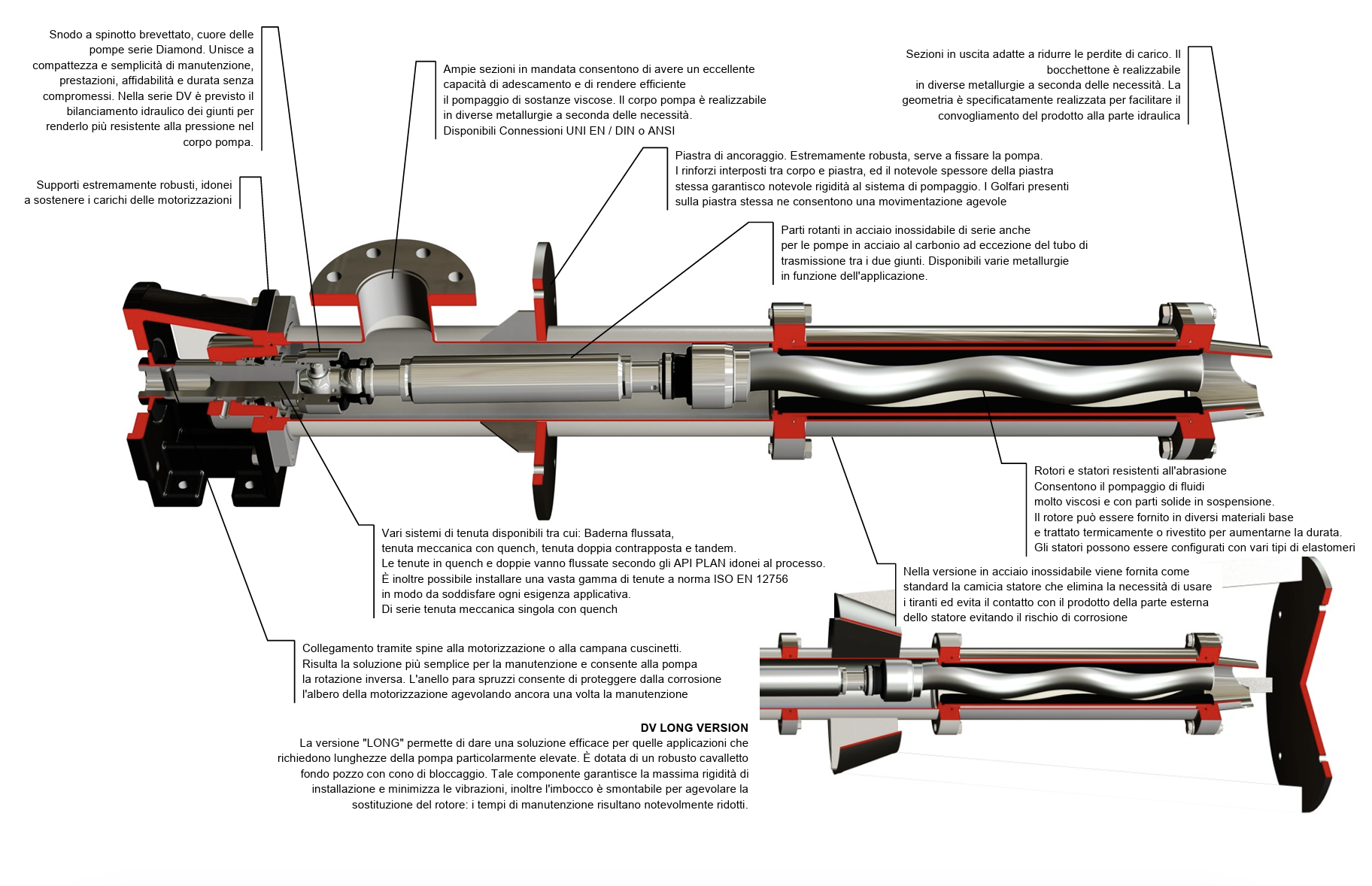

Patented Pin Joint: The pin-type joint, the actual heart of the single screw pump, is the best solution of its type on the market. It offers greater durability, reliability and reduced maintenance costs, managing to combine extreme compactness with unrivalled strength. Its particular manufacturing enables the sub-division of axial loads and torque in different elements, making it one of a kind. As well as the above, replacement of worn parts is cheap thanks to the bushes in the worn zones, avoiding costly replacement of parts (rotor, drive shaft, and female drive shaft. To resist high pressure in the pump casing up to 12 bar, the pin can be hydraulically balanced.

(standard for DV Series).

Materials of Rotors

Steel and special alloy materials with advanced coatings to ensure long-lasting durability and resistance.

Connections

Output sections suitable for reduced load loss. The outlet pipe is manufactured

in various metals based on needs. Connections available UNI EN / DIN or ANSI

The geometry is specifically made to facilitate the flow of the product into the hydraulic part.

Flanges and threaded connections for various applications, including food-grade models and high-pressure environments.

Compliant with UNI, DIN, and ASME standards.

Sealing Systems

Shaft sealing: Different sealing systems can be installed. Each solution is suitable to the specific application. The types available are: single acting mechanical seal, with quench, double acting mechanical seal back to back or tandem, Gland packing with or without flush.

Seals type are interchangeable on the standard pump. Each solution was carefully engineered taking into consideration all the operating conditions. As well as changing the sealing system, you can also install various types of mechanical seals based on the application.

The compartments are suitable for installation of the seals manufactured according to the standards ISO EN 12756. As well as this, it is possible to use cartridge seals from the main manufacturers, also available according to standards API 682 category 1+2

Bases

Base plates: The bottom supports, characterized by considerable thicknesses, are very strong. Available in carbon steel or stainless steel.

Optional

Equipment and optional

DV LONG VERSION

The “LONG" version is an effective solution for those applications with particularly deep wells & tanks. Is supplied with a strong downhole mounting plate with blocking cone. This component ensures maximum stiffness of installation and minimizes vibration, the inlet is removable to facilitate replacement of the rotor: the maintenance times are considerably reduced.

- Temeprature probe for dry running protection (standard in the ATEX version)

- Flow switch

- Stainless steel stator cover

- Industrial flanged Bypass (or with threaded connection)

- Quench Pot flushing

- Stainless Steel Lantern

- Hermetic lantern

- Carter to protect the motorization

(For details, see the brochure constructive options, equipment and installations)

Variants

DV Long version

It is the long version of the vertical series. This version requires a shaft bottom trestle with locking cone to minimize the vibrations and oscillations of the pump caused by the high length of the pump itself. The removable inlet allows access to the rotor-side joint without having to disassemble the entire pump body.

DV Short version

It is the compact version of the vertical series. This version allows installation with only the anchor plate.