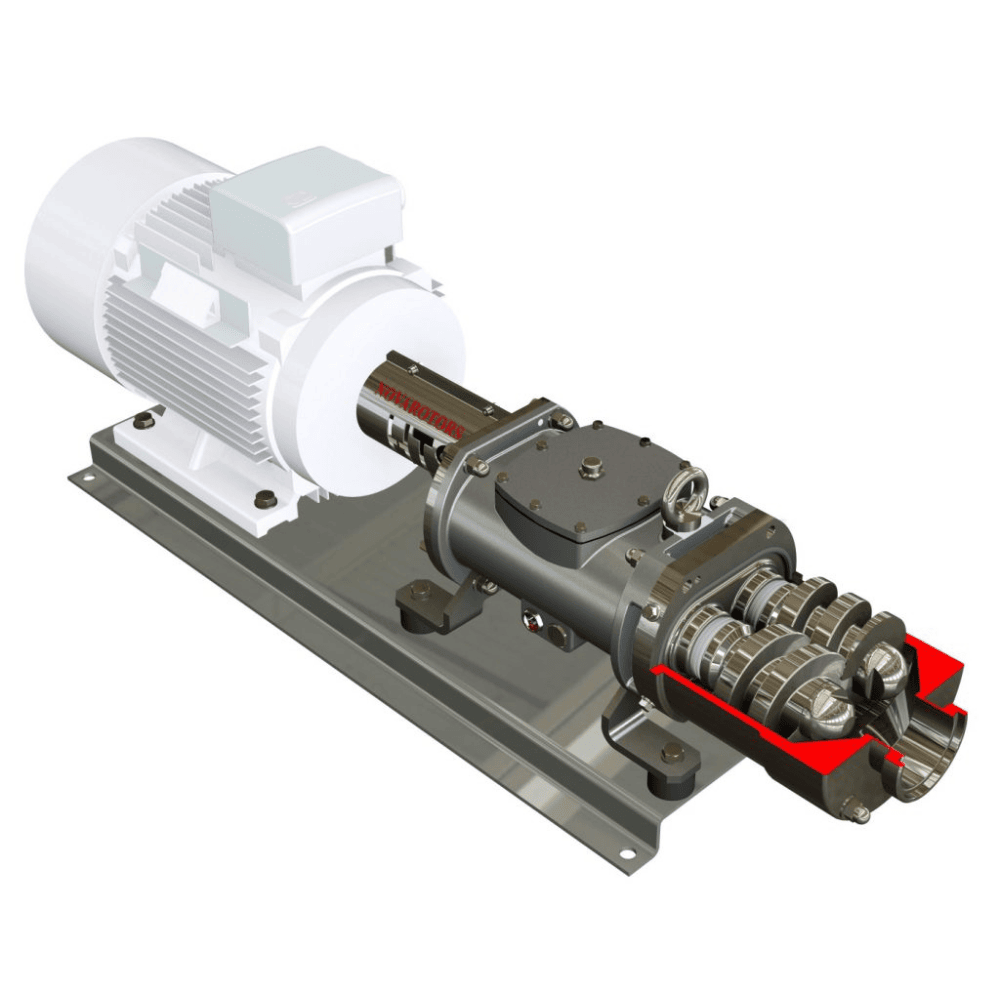

Twin screw pumps HTS Series

Double screw pumps for sanitary food and pharmaceutical sectors

The HTS hygienic series represents the highest level of technology in the field of stainless steel twin-screw sanitary pumps, specifically designed to ensure optimal hygiene in the food and pharmaceutical industries.

Our pride lies in the extremely robust design of these pumps, achieved through an oversized shaft and bearings with a patented gear positioning system.

Key features of twin-screw pumps:

- Gentle handling and reduced pulsations thanks to the axial direction of the product flow.

- High suction capacity with low NPSHr (Net Positive Suction Head required) values.

- No contact or friction between the rotors and the pump body, allowing dry running (only with flushed seals).

- CIP (Cleaning-In-Place) capability and process operation with a single pump.

- High pressure and flow rate despite the compact pump size.

- Suitable for highly viscous liquids (up to 1,000,000 cps).

- Capable of handling solid particles and/or abrasive products.

- Easy and quick maintenance.

- At request certificate 3-A Sanitary standar

- At requet comply to EHEDG food safety

Operating ranges

Flow rate

Pressure

Temperature

Applications

Discover the product's application characteristics Twin screw pumps HTS Series

Materials

Casing materials

Wide selection of alloys and stainless steels, including corrosion-resistant options for harsh environments.

Standard Stainless-Steel gear casing.

Extremely tough with smooth design to avoid pocket.

Allow the installation of 1 radial bearing and 4 angular bearing per shaft, permit max pressure load at both sense of rotation

Seal Shaft Materials

Steel and special alloy materials with advanced coatings to ensure long-lasting durability and resistance.

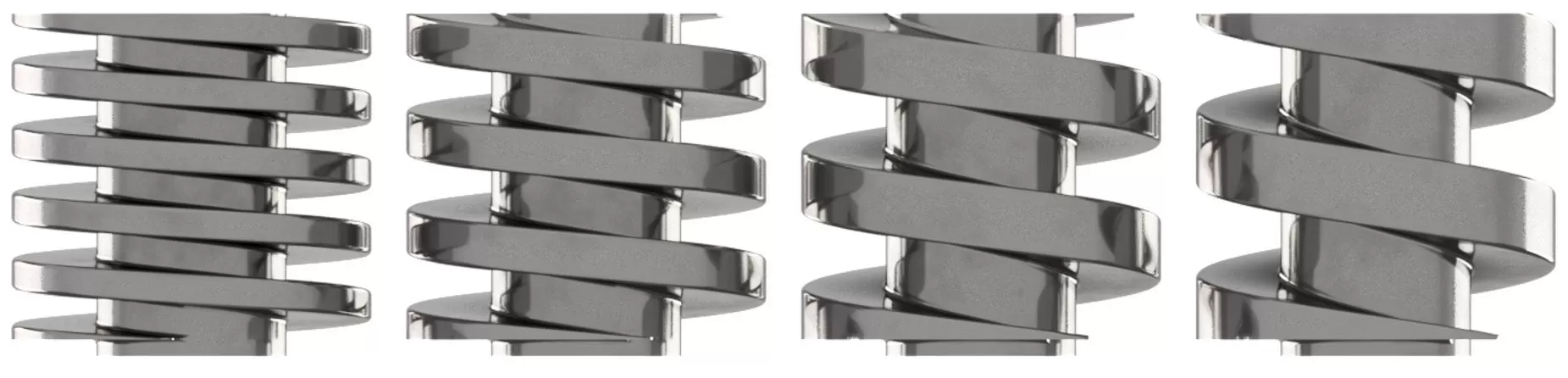

Materials of Rotors

Dynamically balanced Rotors for high speed.

Hardened for abrasive product.

Option to have rotors with four different pitch configurations, depending on the type of product to be pumped. Different pitches allow different flow rates, pressure and solid handling.

kolsterized rotors

Connections

Wide range of fitting standards are available:

DIN 11851, DIN 11864 or Clamp ISO, ASME and other upon request

Sealing Systems

Special hygienic mechanical seal design:

single or double acting, depending on the application.

Possible to change from single to double with a rebuilt

kit, thanks to the modular design of the seals.

Special “knife edge” option for abrasive product

available with Ra<0.8μm

Bases

standard Baseplate

standard Baseplate with 3-A adjustable feet

Hygenic Base frame (meets hygenic recommendations)

Optional

Control devices

Control panel

Control panel with inverter

Drive with integrated inverter

Equipment and optional

Heating jacket

Quench Pot flushing

Drive Cover

Features in detail

Rotors

Dynamically balanced rotors for high-speed operation. DetailsConnections

A wide range of adaptation standards is available: DetailsStandard stainless steel gearbox

Extremely streamlined design to prevent stagnation DetailsInspection hatch

Inspection door with vent DetailsLubrication

Oil recirculation channels and specially designed gear geometries DetailsRotors

Rotor locking system consisting of a keyless locking device DetailsMechanical seals

Special hygienic mechanical seal design: DetailsBody pump

316L body material. DetailsGasket

Hygienic design to prevent dead zones. Details

-

1

Rotors

Dynamically balanced rotors for high-speed operation.

Hardened for abrasive products.

Different pitches allow for various flow rates, pressures, and solid handling. -

2

Connections

A wide range of adaptation standards is available:

DIN 11851, DIN 11864, or Clamp ISO, ASME, and others on request.

Standard stainless steel gearbox.

Extremely linear design to prevent stagnation. -

3

Standard stainless steel gearbox

Extremely streamlined design to prevent stagnation

Allows the installation of 1 radial bearing and 4 angular contact bearings per shaft, ensuring maximum pressure load in both rotation directions.

-

4

Inspection hatch

Inspection door with vent

Inspection port for easy and quick maintenance checks.

-

5

Lubrication

Oil recirculation channels and specially designed gear geometries

ensure proper lubrication of all rotating parts.

-

6

Rotors

Rotor locking system consisting of a keyless locking device

Rotor locking system consisting of a keyless locking device and specially hardened gears, designed to withstand high rotational speeds for long periods.

-

7

Mechanical seals

Special hygienic mechanical seal design:

Single or double depending on the application.

Thanks to the modular design, a kit allows conversion from a single to a double seal.

Special "knife-edge" face design for abrasive products, available with Ra < 0.8 µm. -

8

Body pump

316L body material.

Optional body coating hardening treatment for highly abrasive products.

Reduced clearance to improve suction capacity.

Low roughness for product contact surfaces: Ra < 0.8 µm. -

9

Gasket

Hygienic design to prevent dead zones.

Gasket available in various FDA-approved elastomers.

Further details

Dynamically balanced rotors for high-speed operation.

Hardened for abrasive products.

Different pitches allow for various flow rates, pressures, and solid handling.

Further details

A wide range of adaptation standards is available:

DIN 11851, DIN 11864, or Clamp ISO, ASME, and others on request.

Standard stainless steel gearbox.

Extremely linear design to prevent stagnation.

Further details

Extremely streamlined design to prevent stagnation

Allows the installation of 1 radial bearing and 4 angular contact bearings per shaft, ensuring maximum pressure load in both rotation directions.

Further details

Inspection door with vent

Inspection port for easy and quick maintenance checks.

Further details

Oil recirculation channels and specially designed gear geometries

ensure proper lubrication of all rotating parts.

Further details

Rotor locking system consisting of a keyless locking device

Rotor locking system consisting of a keyless locking device and specially hardened gears, designed to withstand high rotational speeds for long periods.

Further details

Special hygienic mechanical seal design:

Single or double depending on the application.

Thanks to the modular design, a kit allows conversion from a single to a double seal.

Special "knife-edge" face design for abrasive products, available with Ra < 0.8 µm.

Further details

316L body material.

Optional body coating hardening treatment for highly abrasive products.

Reduced clearance to improve suction capacity.

Low roughness for product contact surfaces: Ra < 0.8 µm.

Further details

Hygienic design to prevent dead zones.

Gasket available in various FDA-approved elastomers.

- Dynamically balanced rotors for high-speed operation.

Hardened for abrasive products.

Different pitches allow for various flow rates, pressures, and solid handling. - A wide range of adaptation standards is available:

DIN 11851, DIN 11864, or Clamp ISO, ASME, and others on request.

Standard stainless steel gearbox.

Extremely linear design to prevent stagnation. - Allows the installation of 1 radial bearing and 4 angular contact bearings per shaft, ensuring maximum pressure load in both rotation directions.

- Inspection port for easy and quick maintenance checks.

- Oil recirculation channels and specially designed gear geometries ensure proper lubrication of all rotating parts.

- Rotor locking system consisting of a keyless locking device and specially hardened gears, designed to withstand high rotational speeds for long periods.

- Special hygienic mechanical seal design: Single or double depending on the application.

Thanks to the modular design, a kit allows conversion from a single to a double seal.

Special "knife-edge" face design for abrasive products, available with Ra < 0.8 µm. - 316L body material.

Optional body coating hardening treatment for highly abrasive products.

Reduced clearance to improve suction capacity.

Low roughness for product contact surfaces: Ra < 0.8 µm. - Gasket available in various FDA-approved elastomers.

Hygienic design to prevent dead zones.

Rotors pitch