WINE INDUSTRY

The wine-making industry has always played an important role in the history of humanity in both economic and social terms. The wine tradition has such ancient origins that its roots are buried in legends: the Bible attributes the discovery of wine to Noah after the Flood. The earliest historical documents that bear witness to the production of wine date as far back as 5000 B.C. in Mesopotamia in the Fertile Crescent, where the ancient Sumerians began cultivating wild grape vines and fermenting grapes.

Currently in Italy and in countries like France and Spain the wine making industry is a leading sector in continual change that is investing heavily in the development of new viticulture and winemaking techniques, with the aim of producing an ever higher quality of wine.

The winemaking process varies depending on the type of wine to be produced and includes all processing and fermentation stages from the delivery of the grapes to the final product.

Progressive cavity pumps are ideal for the various process stages as they convey the fluid throughout the entire process in a particularly delicate way, from the berry crushing stage through to the bottling of the wine. The tensile stress to which the pumped fluid is subjected is very limited compared to other pumping systems being pulsation-free above all with heterogeneous products such as for example pomace and crushed and destemmed grapes.

WHY CHOOSE NOVA ROTORS?

Nova Rotors has worked in the winemaking industry for years seeking to provide the best possible solutions, a wide range of products, services and experts to find the most suitable configuration based on the customer’s specific requirements. The various testimonials received from our customers around the world over the years attest to the commitment of a dynamic company focussed on meeting the constantly growing market demands.

Nova Rotors progressive cavity pumps are developed scrupulously in compliance with the strictest hygiene and industrial standards to guarantee high standards of quality, reliability and duration, by providing the best solutions throughout the entire winemaking process. In particular special attention has been given to each transition from one process stage to the next, by making various construction types available in order to optimise each and every transfer.

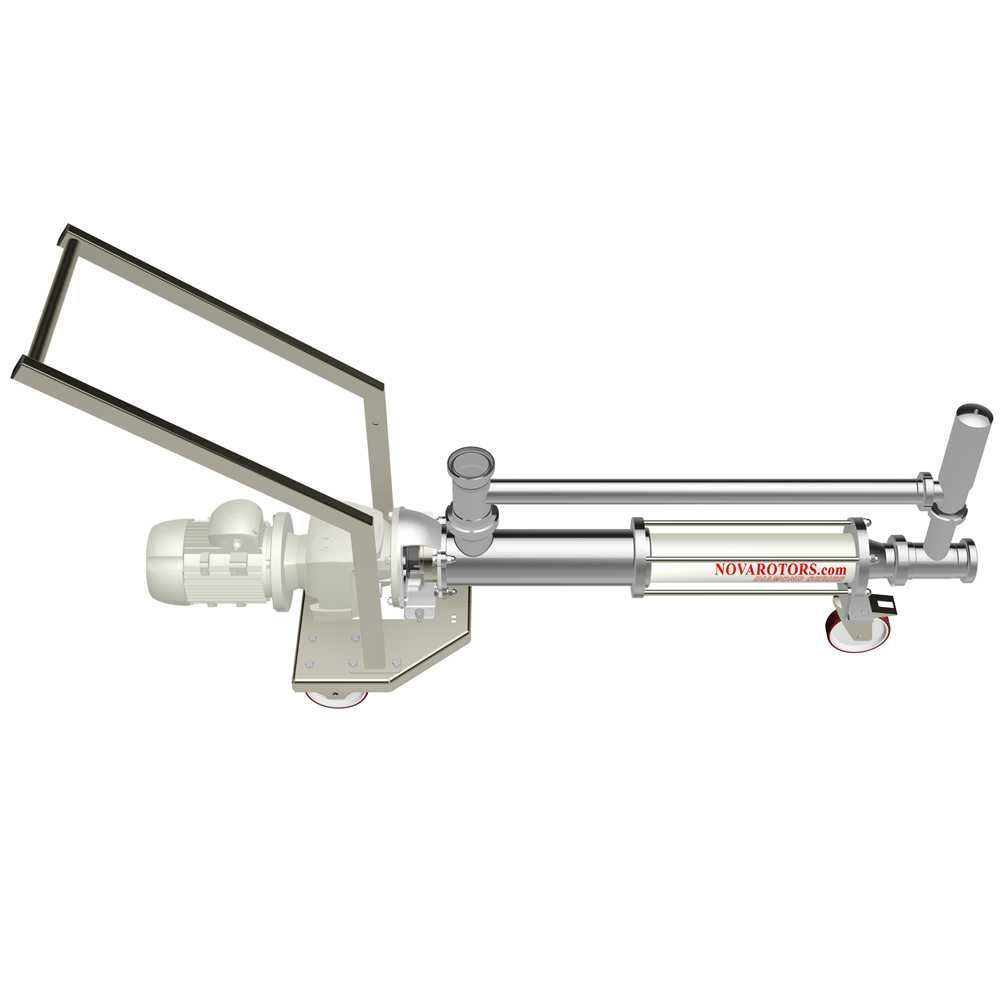

DX-E

Typical pump for oenological use

with bypass and trolley

FLOW CHART

Application (refer to the above diagram):

- DHE: pump designed specifically for the winemaking industry, used for pumping crushed and destemmed must from the crusher-destemmer to the fermenter

- DHP: hopper pump with bridge breaker blades for pumping pomace that is prone to bridging from the fermenter to the pomace press

- DX: pump designed specifically for the food industry used to convey the wine and must from the fermenter or from the pomace press to the stainless steel tank

- DX: pump used to convey wine from the stainless steel tank to the subsequent wine filtering stage

- RL: compact stainless steel wobble pump used to convey the filtered wine to the subsequent bottling stage

Product for wine industry

DN SERIES

Flanged industrial series ideal for heavy duty applications. It is the best solution for the industrial sector for pumping a vast range of fluids; available with UNI, DIN and ANSI flanged and GAS BSP threaded connections.

DH SERIES

Standard model equipped with hopper and auger feed screw to move the product to the hydraulic part. Suitable for pumping materials with a low degree of flowability and prone to bridging.

DHE SERIES

Model with a large eccentric hopper and integrated trolley, ideal in the winemaking industry for pumping crushed grapes with or without the stems. Standard AISI 304 stainless steel construction for all components.

DHP SERIES

Model with enlarged hopper and auger feed screw to move the product to the hydraulic part, ideal for pumping materials with a low degree of flowability and prone to bridging. Standard AISI 304 or AISI 316 stainless steel construction.

DXO SERIES

The DXO series is the hygienic pump with open joint. The design of its casing and rotating parts that are completely free of standing water and dead zones makes it the absolute best sanitizing solution.

DXC SERIES

The DXC series is a hygienic pump with standard DN series joint. It is the solution that combines excellent sanitizing characteristics thanks to the design of its casing that is completely free of standing water and dead zones, with the top performing patented pin joint of the Diamond series.

RL SERIES

The RL series is an extremely compact product thanks to the integrated pump-electric motor construction. The patented pin joint of the Diamond series ensures high reliability.

R SERIES

The R series is the most compact product available due to the elimination of the block between the pump and the drive. It uses a cross joint, is reliable and easy to maintain.

APPLICATIONS

DN Pump

Transfer of wine from stainless steel tanks to wood barrels for aging.

The transfer occurs without any tensile stress and is pulse-free to retain the organoleptic characteristics of the wine.

DN Pump

Transfer of the must obtained from pressing the pomace to the tanks for the next aging stage.

DHE Pump

Transfer of the fermented pomace from the tank to the press

using a trolley-mounted press. The enlarged screw guarantees a constant flow rate.

DH Pump

Transfer of pomace and must from the crusher-destemmer

using a hopper pump connected directly to the machinery.

Brochure Winery foodgrade sector

Application sector

lang: English

Brochure sector Enològico

Application sector

lang: español

Brochure settore Enologia

Settore di Applicazione

lang: Italiano

Brochure oenoligique

Secteur d’application

lang: Francais