Positive displacement pumps in water treatment: efficiency and environmental sustainability

Positive displacement pump technology for water treatment

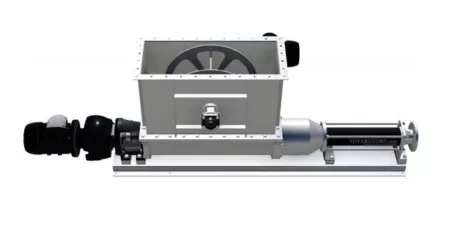

Positive displacement pumps by Nova Rotors represent the advanced technological solution for optimizing purification processes and ensuring environmental sustainability in water treatment plants. With over 30 years of specialized experience, Nova Rotors has developed innovative solutions for water purification pumps and wastewater treatment pumps that combine operational efficiency and ecological responsibility. The Diamond N series progressive cavity pumps effectively handle sludge with dry matter percentages up to 40%, ensuring continuous 24/7 performance with flow rates up to 420 m³/h and pressures up to 48 bar. The integrated Nova Rotors system for waste disposal pumps includes Terminator grinders and chemical reagent dosing pumps, optimizing every phase of the purification process. The environmental benefits derived from using Nova Rotors positive displacement pumps include energy consumption reduction up to 30%, precise dosing of chemical reagents that minimizes environmental impact, and reduction of noise pollution in urban plants. Progressive cavity technology ensures gentle fluid transfer, preserving the integrity of biological processes and supporting the transition towards a sustainable circular economy.

Nova Rotors positive displacement pumps are based on the innovative principle of progressive cavity, a technology that ensures superior performance in the water treatment sector compared to conventional pumping systems. The design of Diamond progressive cavity pumps creates sealed chambers that move progressively along the pump axis, generating a uniform and continuous flow without pulsations.

This characteristic is fundamental in water purification pumps as it preserves the integrity of biological processes characteristic of activated sludge systems. Nova Rotors positive displacement pumps eliminate excessive mechanical stress on purifying microorganisms, maintaining the efficiency of the biological process and ensuring the quality of the final effluent.

The Diamond N series represents Nova Rotors' technological excellence for water treatment applications, incorporating corrosion-resistant materials and modular design that facilitates maintenance. Positive displacement pumps offer operational flexibility by handling fluids with variable physical-chemical characteristics, from low-concentration primary sludge to high-density thickened sludge.

Applications of pumps for water purification

Water purification pumps by Nova Rotors are used in all critical phases of the purification process, from raw wastewater collection to final treatment of produced sludge. The versatility of positive displacement pumps enables effective management of complex fluids characteristic of civil and industrial purification plants.

In primary treatment, positive displacement pumps transfer sedimentation sludge to thickeners, maintaining constant rheological characteristics of the material. The ability to handle variable dry matter percentages from 2% to 6% makes Diamond pumps ideal for optimizing thickening processes and reducing volumes to be treated in subsequent phases.

Secondary treatment requires water purification pumps capable of handling active biological sludge without compromising the vitality of microorganisms. Nova Rotors positive displacement pumps ensure gentle transfer of biological sludge from oxidation basins to secondary clarifiers, preserving the efficiency of the biological purification process.

In tertiary treatment phases, positive displacement pumps handle chemical-physical sludge derived from coagulation and flocculation processes, effectively transferring them to mechanical dewatering systems such as centrifuges and filter presses.

Efficient management of wastewater treatment pumps

Nova Rotors wastewater treatment pumps are specifically designed to address the operational challenges of modern purification plants, where operational reliability and energy efficiency represent absolute priorities. Volumetric technology ensures constant performance even with significant variations in the characteristics of the treated fluid.

Industrial wastewater treatment plants present specific requirements related to the nature of contaminants present. Nova Rotors positive displacement pumps effectively handle wastewater containing oils, fats, heavy metals, and aggressive chemical substances, thanks to the availability of specialized construction materials and advanced protective coatings.

The flanged industrial series ensures compatibility with international API 676 standards, ensuring regulatory compliance for installations in critical industrial plants. Wastewater treatment pumps are available with ATEX certifications for installation in potentially explosive environments, a fundamental characteristic in the petrochemical and pharmaceutical sectors.

The modular construction of positive displacement pumps facilitates scheduled maintenance, reducing plant downtime and optimizing operational costs. The Nova Rotors design allows rapid access to critical components, simplifying inspection operations and replacement of spare parts.

Waste disposal pumps and circular economy

The waste disposal sector requires innovative technological solutions capable of transforming water treatment by-products into valuable resources according to circular economy principles. Nova Rotors waste disposal pumps support this transition through integrated systems that optimize energy recovery and material reuse.

Terminator TG series grinders integrate perfectly with positive displacement pumps to create complete solids pre-treatment systems. This technological combination prevents blockages, reduces wear on downstream components, and improves the overall efficiency of the waste disposal process.

Nova Rotors positive displacement pumps effectively transfer dewatered sludge to energy recovery systems such as anaerobic digesters for biogas production or incineration plants for thermal recovery. The ability to handle sludge with dry matter percentages up to 40% optimizes the energy balance of these processes.

For composting and agricultural use applications, waste disposal pumps ensure gentle transfer of stabilized sludge, preserving agronomic characteristics and minimizing organic matter degradation during transport.

Precise dosing of chemical reagents

Optimization of water treatment processes requires precise dosing of chemical reagents for coagulation, flocculation, pH correction, and disinfection. Nova Rotors M series dosing pumps represent the ideal solution for these critical applications, ensuring accuracy and repeatability in dosing.

The volumetric technology of dosing pumps ensures dosing precision independent of system pressure variations, a fundamental characteristic for maintaining constant optimal conditions of the chemical-physical process. This precision significantly reduces chemical reagent consumption, minimizing environmental impact and operational costs.

Nova Rotors dosing pumps effectively handle aggressive chemical reagents such as polyaluminum chloride, polyelectrolytes, hydrated lime, and sodium hypochlorite, thanks to the availability of chemically compatible materials and specialized sealing systems.

The modularity of dosing pumps allows multiple configurations for simultaneous dosing of different reagents, optimizing plant automation and reducing management complexity. Integrated control systems ensure proportional dosing to treated flow rates, maximizing the efficiency of the purification process.

Environmental benefits of positive displacement pumps

The implementation of Nova Rotors positive displacement pumps in water treatment plants generates significant environmental benefits that contribute to achieving European sustainability goals. The reduction in energy consumption represents the main environmental advantage, with savings up to 30% compared to conventional pumping systems.

Optimized energy efficiency:

- Progressive cavity technology with efficiencies exceeding 85%

- Elimination of recirculation losses typical of centrifugal pumps

- Variable speed operation for automatic adjustment to flow requirements

- Reduction of head losses thanks to laminar flow

- Minimization of electrical energy consumption in purification plants

Reduction of chemical impact:

- Precise dosing of chemical reagents with waste reduction up to 20%

- Minimization of chemical sludge production through process optimization

- Reduction in the use of additives for foam and odor control

- Improvement of effluent quality with lower use of disinfectants

- Support for natural biological processes reducing the need for chemical interventions

Noise pollution control represents a further environmental benefit of Nova Rotors positive displacement pumps. The silent operation, with sound levels below 70 dB(A), reduces acoustic impact in plants located in urban and peri-urban areas, improving the environmental compatibility of purification infrastructures.

Advanced management of complex fluids

Nova Rotors positive displacement pumps excel in handling complex fluids characteristic of water treatment, where the presence of suspended solids, fibers, oils, and viscous substances requires specialized technologies. The ability to handle fluids with solid content up to 40% by weight makes these pumps ideal for all phases of the purification process.

Primary sludge, characterized by high compositional variability and presence of fibrous materials, is effectively transferred without risks of obstruction or damage to internal components. Progressive cavity technology tolerates the presence of small solid objects, reducing pre-treatment costs and simplifying operational management.

Biological sludge, containing living microorganisms sensitive to mechanical stress, requires gentle transfer to preserve biological activity. Nova Rotors positive displacement pumps ensure optimal velocity gradient, avoiding the breaking of biological flocs and maintaining the efficiency of biological purification processes.

The management of chemical-physical sludge, often characterized by non-Newtonian rheological properties and tendency to sedimentation, requires pumps capable of keeping solids in suspension during transfer. Positive displacement pumps ensure adequate drag velocities, preventing deposits in pipelines and ensuring homogeneity of the pumped fluid.

Operational reliability and service continuity

Operational continuity represents a fundamental requirement in water treatment plants, where unscheduled interruptions can cause spillage of untreated wastewater with serious environmental consequences. Nova Rotors positive displacement pumps are designed for continuous 24/7 operation, ensuring reliability even in the most demanding operating conditions.

The robust design and quality of construction materials ensure exceptional operational durability, with life cycles exceeding 100,000 operating hours for standard applications. The availability of original spare parts and specialized technical support ensure minimum restoration times in case of maintenance interventions.

The standardization of critical components simplifies spare parts warehouse management and reduces scheduled maintenance costs. Nova Rotors maintenance kits include all necessary components for complete interventions, optimizing plant downtime and ensuring rapid restoration of optimal operating conditions.

Integrated monitoring systems allow predictive diagnosis of operating conditions, anticipating any anomalies and scheduling maintenance interventions before failures occur. This predictive capability optimizes maintenance planning and maximizes the operational availability of the purification plant.

Technological innovation and sustainable development

Nova Rotors constantly invests in research and development to anticipate the future needs of the water treatment sector, focusing on innovations that combine superior performance and environmental sustainability. New generations of positive displacement pumps incorporate advanced materials, nanotechnological coatings, and intelligent control systems.

The development of hybrid positive displacement pumps, which combine the robustness of progressive cavity pumps with the efficiency of digital technologies, represents the frontier of Nova Rotors innovation. The integration of IoT sensors and artificial intelligence algorithms automatically optimizes operational parameters, maximizing efficiency and minimizing consumption.

The sustainability of construction materials guides Nova Rotors design choices, favoring recyclable steels, biodegradable elastomers, and eco-compatible coatings. This attention to the sustainability of product life cycles supports the transition towards a circular economy also in the water treatment technology sector.

Specialized training of operating personnel represents a strategic investment to optimize the environmental performance of plants. Nova Rotors offers technical training programs that develop specific skills for sustainable management of positive displacement pumps, maximizing operational efficiency and reducing the environmental impact of purification processes.