On request, steel support base.

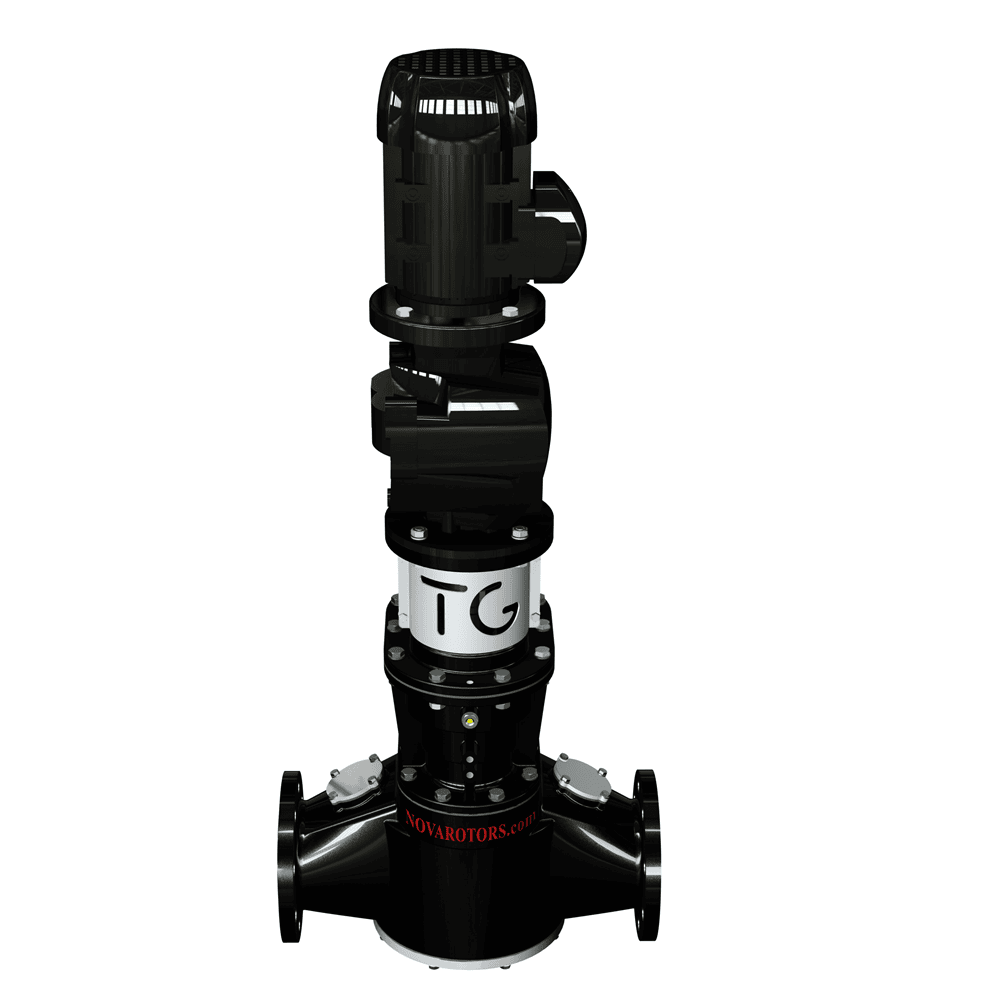

Grinders | TERMINATOR

Grinder TG series

Shredder for industrial and ecological sector

Nova Rotors Grinders – TG Series

A uniform and proper treatment of solids is essential, particularly in wastewater treatment applications and sludge management systems. It is also crucial in other industries to prevent harmful solids from entering the pumping system.

Selecting the right solution at the best cost can be challenging.

Our TG series for solid size reduction is one of the most innovative solutions available on the market.

We take pride in our extremely robust design, combined with a flexible internal component configuration. This approach ensures optimal performance while maintaining cost savings.

Additionally, the accessories and options we have developed allow us to create a true "All-in-One Grinder System."

Key features and benefits of our grinders:

1. Protection of Downstream Equipment

- Shields pumps from damaging solids.

- Extends the lifespan of wear-prone components.

- Safeguards critical equipment from damage caused by hard solids.

- Significantly reduces unexpected downtime.

2. Proper Treatment Operations

- Blocks inorganic materials while allowing organic matter to remain in the process.

- More processed material means less waste compared to traditional screening.

- Organic material reduction enhances overall process quality.

3. Operational Cost Reduction

- Enables the use of smaller downstream pipes and pumps.

- Shorter pump cycles and lower energy consumption.

- Improved facility cleanliness.

✔ Available with an electrical control panel featuring a reverse function in case of excessive load.

Operating ranges

Flow rate

Flow up to 100 m³/h – 450 gmp.

Pressure

Temperature

from -20°c + 65°c

Applications

Discover the product's application characteristics Grinder TG series

Materials

Casing materials

G25 cast iron body, for corrosion-resistant operations and for harsh environments.

Seal Shaft Materials

Steel materials to ensure long life and resistance.

Materials of Rotors

Interchangeable steel knives to ensure long life and resistance.

Connections

Flanges and threaded connections for various applications, including food models and for high-pressure environments.

Sealing Systems

Cartridge mechanical seals also with flushing solutions.

Bases

Optional

Supplied on request with an electrical panel with a reverse gear system in case of excessive strain.

Support base.

version with opposing bearings

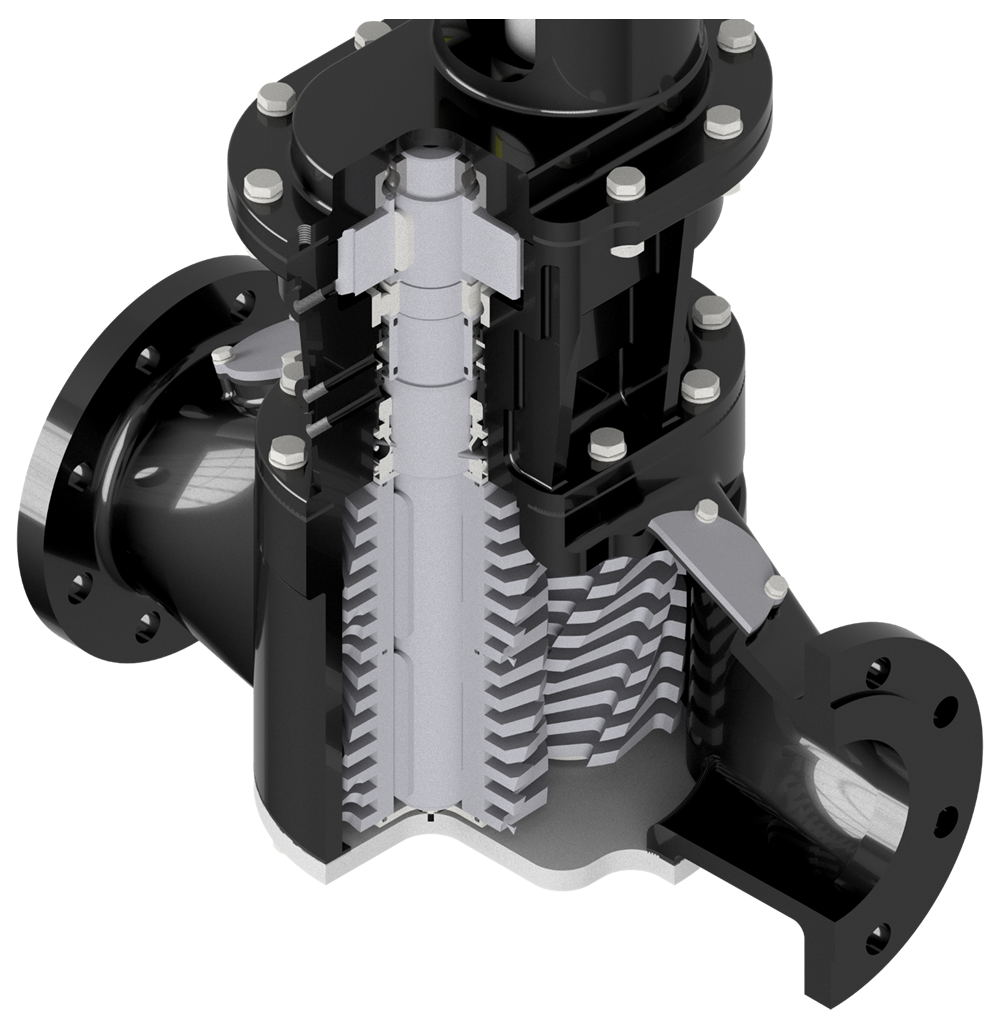

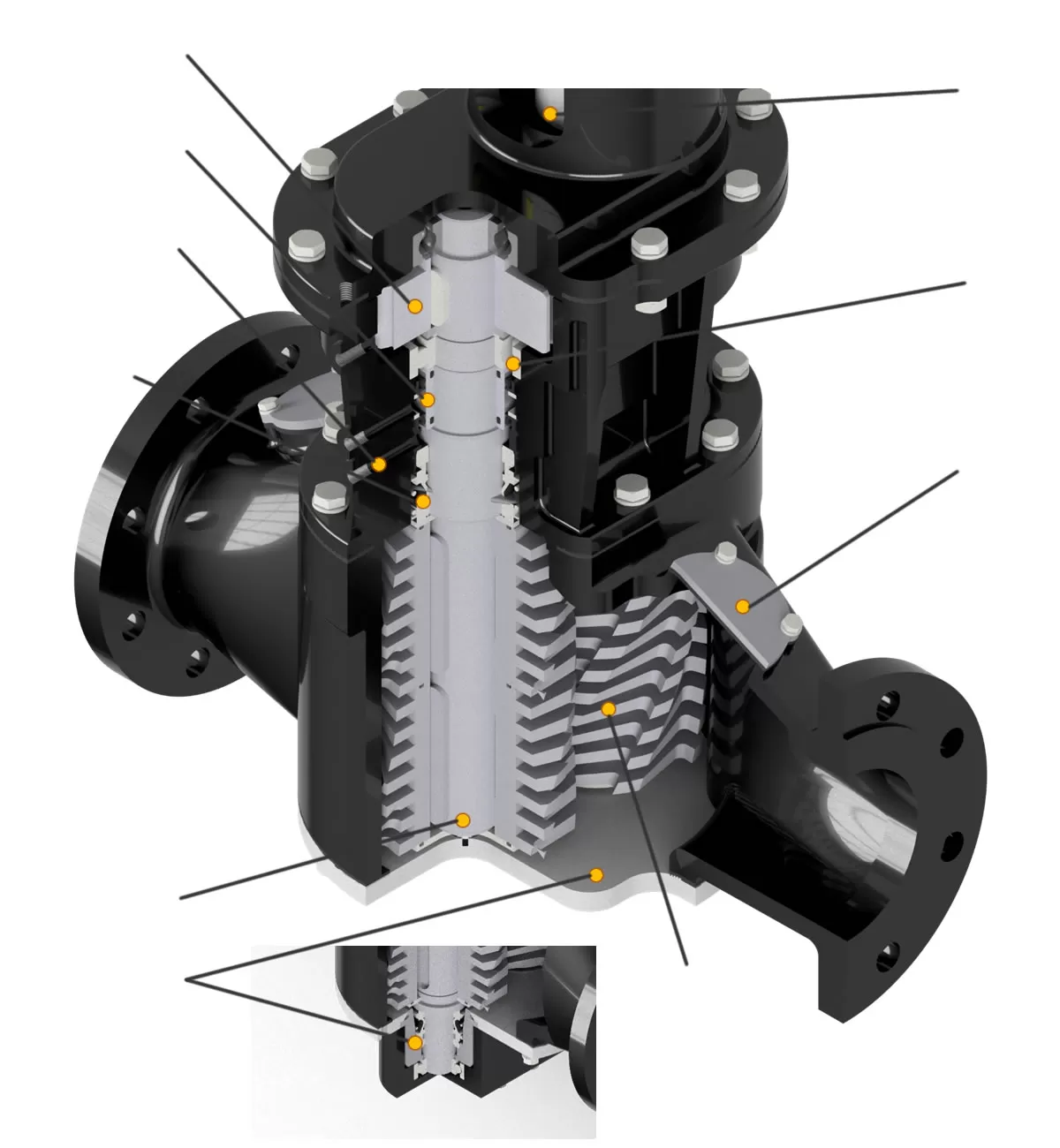

Features in detail

1

Gear module

Long-life gear module. Details2

Shredder shaft support bushing, surface-treated

Inspection of the connection for possible leaks (from the process side or the gear side). Details3

Lubricant inlet duct for the mechanical seal

Easier maintenance and extended seal service life. Details4

Cartridge mechanical seal supplied as standard

Design compatible with many types of seals. Details5

AISI 420B shaft material with high mechanical properties

Standard shaft designed to support the second bearing. Details6

Standard closure cover

Easy solution for inspecting or replacing the cutting edges. Details7

Two types of hardened steel for high resistance

The cutting edges are standard cartridge type for all sizes. Details8

Standard inspection doors on both sides

For checking waste and flow. Details9

Bearing support material in cast iron

Oversized bearing. Details10

Standard Ø200 driver connection

Slow rotation, high torque at low power. Details

-

1

Gear module

Long-life gear module.

Oil-immersed. Constant oil level indicator.

-

2

Shredder shaft support bushing, surface-treated

Inspection of the connection for possible leaks (from the process side or the gear side).

Structural component designed to support the drive shaft, improve wear resistance, and allow quick inspection of any leakage from the process side or the gear side.

-

3

Lubricant inlet duct for the mechanical seal

Easier maintenance and extended seal service life.

Thanks to lubricated cartridge seals, supplied by a small cup reservoir, our shredders require less maintenance, avoiding complex interventions and reducing downtime.

-

4

Cartridge mechanical seal supplied as standard

Design compatible with many types of seals.

Cartridge mechanical seal supplied as standard, supported by a lubrication system with a double lubricant container to increase seal service life.

The shredder design allows the use of various types of mechanical seals. -

5

AISI 420B shaft material with high mechanical properties

Standard shaft designed to support the second bearing.

O-ring and gasket for protection and easy maintenance.

Cutting units can be removed without disconnecting the shafts. -

6

Standard closure cover

Easy solution for inspecting or replacing the cutting edges.

In the TG version (without opposed bearings), the stone collector can be easily adapted.

Also available in the TGS version with double bearings to ensure greater robustness in more demanding applications. -

7

Two types of hardened steel for high resistance

The cutting edges are standard cartridge type for all sizes.

Reduced spare parts. Very simple maintenance of the cutting units.

-

8

Standard inspection doors on both sides

For checking waste and flow.

Useful for viewing the inside of the body and any blockages.

Facilitates inspection of the cutting edges, allowing quick checking of blade wear and integrity. -

9

Bearing support material in cast iron

Oversized bearing.

Standard component for the available range.

-

10

Standard Ø200 driver connection

Slow rotation, high torque at low power.

Standard coupling for easy maintenance.

Multiple solution for motor and/or gearbox.

Further details

1

Gear module

Long-life gear module.

Oil-immersed. Constant oil level indicator.

Further details

2

Shredder shaft support bushing, surface-treated

Inspection of the connection for possible leaks (from the process side or the gear side).

Structural component designed to support the drive shaft, improve wear resistance, and allow quick inspection of any leakage from the process side or the gear side.

Further details

3

Lubricant inlet duct for the mechanical seal

Easier maintenance and extended seal service life.

Thanks to lubricated cartridge seals, supplied by a small cup reservoir, our shredders require less maintenance, avoiding complex interventions and reducing downtime.

Further details

4

Cartridge mechanical seal supplied as standard

Design compatible with many types of seals.

Cartridge mechanical seal supplied as standard, supported by a lubrication system with a double lubricant container to increase seal service life.

The shredder design allows the use of various types of mechanical seals.

Further details

5

AISI 420B shaft material with high mechanical properties

Standard shaft designed to support the second bearing.

O-ring and gasket for protection and easy maintenance.

Cutting units can be removed without disconnecting the shafts.

Further details

6

Standard closure cover

Easy solution for inspecting or replacing the cutting edges.

In the TG version (without opposed bearings), the stone collector can be easily adapted.

Also available in the TGS version with double bearings to ensure greater robustness in more demanding applications.

Further details

7

Two types of hardened steel for high resistance

The cutting edges are standard cartridge type for all sizes.

Reduced spare parts. Very simple maintenance of the cutting units.

Further details

8

Standard inspection doors on both sides

For checking waste and flow.

Useful for viewing the inside of the body and any blockages.

Facilitates inspection of the cutting edges, allowing quick checking of blade wear and integrity.

Further details

9

Bearing support material in cast iron

Oversized bearing.

Standard component for the available range.

Further details

10

Standard Ø200 driver connection

Slow rotation, high torque at low power.

Standard coupling for easy maintenance.

Multiple solution for motor and/or gearbox.

DETAILED FEATURES

The main features and benefits of the grinders are:

Downstream equipment protection

- Protects pumps from harmful solids

- Increases the lifespan of wear-prone components

- Shields critical equipment from damage caused by tough solids

- Significantly reduces unexpected downtime

Proper treatment operations

- Blocks inorganic material while allowing organic material to remain in the process

- More processed material means less waste compared to screening

- Reducing organic material improves process quality

Lower operating costs

- Allows the use of smaller pipes and pumps downstream

- Shorter pump operating cycles and reduced power consumption

- Improved plant cleanliness

Advantages of Our TG Grinders:

1. High Efficiency in Solid Reduction

TG grinders are designed to ensure uniform and rapid solid size reduction, optimizing wastewater and sludge treatment, and improving overall system efficiency.

2. Durability and Strength

A robust structure and high-quality materials ensure long service life, even in demanding environments, reducing frequent maintenance needs and increasing operational reliability.

3. Easy Maintenance

Equipped with lubricated cartridge seals, powered by a small cup reservoir, our grinders require minimal maintenance, eliminating complex interventions and reducing downtime.

4. Flexibility

The modular configuration allows adaptation to specific plant requirements, with customizable accessories and options available.

5. Energy Savings

TG grinders help reduce energy consumption through efficient component design, optimizing work cycles and lowering electricity usage.

6. Critical Equipment Protection

Protects pumps and facilities from hard solid damage, extending equipment lifespan and reducing replacement costs. help reduce energy consumption through efficient component design, optimizing work cycles and lowering electricity usage.

6. Critical Equipment Protection

Protects pumps and facilities from hard solid damage, extending equipment lifespan and reducing replacement costs.